EPDM sealing strip classification material knowledge

Published:

2024-01-19

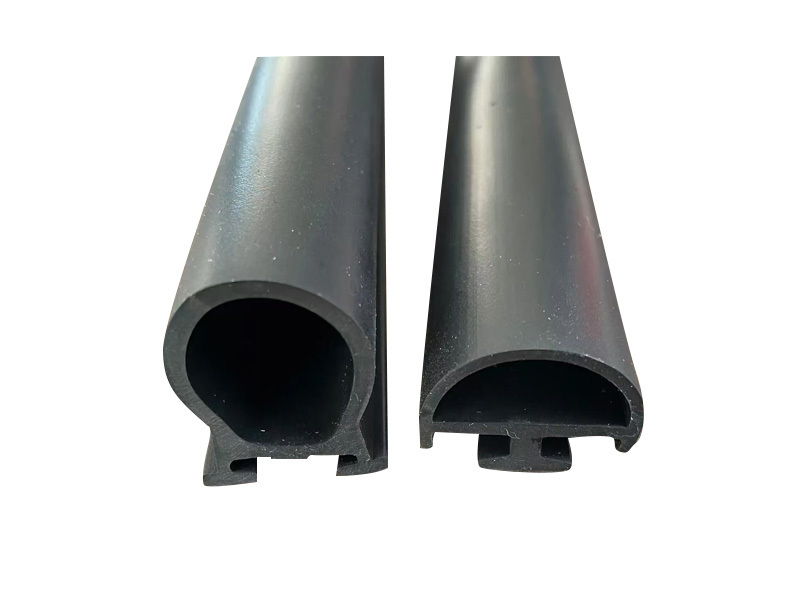

EPDM rubber strip can be divided into two categories according to EPDM sealing strip data: dense rubber strip and foamed rubber strip. The hardness of dense rubber strip is generally between 65 degrees and 90 degrees. The hardness of foamed rubber strip is between 15 degrees and 35 degrees. The product is soft and has good resilience. It is suitable for various sealing blocks, gaskets, etc.

EPDM rubber strip can be divided into two categories according to EPDM sealing strip data: dense rubber strip and foamed rubber strip. The hardness of dense rubber strip is generally between 65 degrees and 90 degrees. The hardness of foamed rubber strip is between 15 degrees and 35 degrees. The product is soft and has good resilience. It is suitable for various sealing blocks, gaskets, etc.

EPDM sealing strip according to the vulcanization method can be divided:

(1) Non-continuous vulcanization method (after cutting the extruded rubber strip according to a certain length, it is put into a vulcanization tank for vulcanization, and the semi-finished products of the extruded rubber strip are put into the model for vulcanization);

(2) Successive vulcanization method (microwave successive vulcanization method, salt bath successive vulcanization method, hot air successive vulcanization method and other methods). A. Microwave vulcanization composite sealing strip: Microwave vulcanization technology is a production technology that has been widely used and widely promoted after the foreign energy crisis in the 1970 s. The use of microwave vulcanization technology can not only produce a variety of materials from the metal core, dense glue and foam co-extrusion, but also, in terms of energy saving, running power and other aspects of the operation than other continuous vulcanization equipment. This technology is recognized by the world as a good way to produce extruded products. The characteristic of microwave heating is that the heat occurs directly in the heated object, instead of being input from the outside as usual, so that not only the heat is fast, but also the distribution is uniform, which is conducive to the quality of the traveling product and greatly shortens the heating time. B. salt bath continuous vulcanization rubber strip: salt bath vulcanization uses salt bath system containing nitrite, which has great pollution to the environment and has been gradually selected.

Sealant Strip Common Sense

Selection of Sealing Strip for Building Doors and Windows

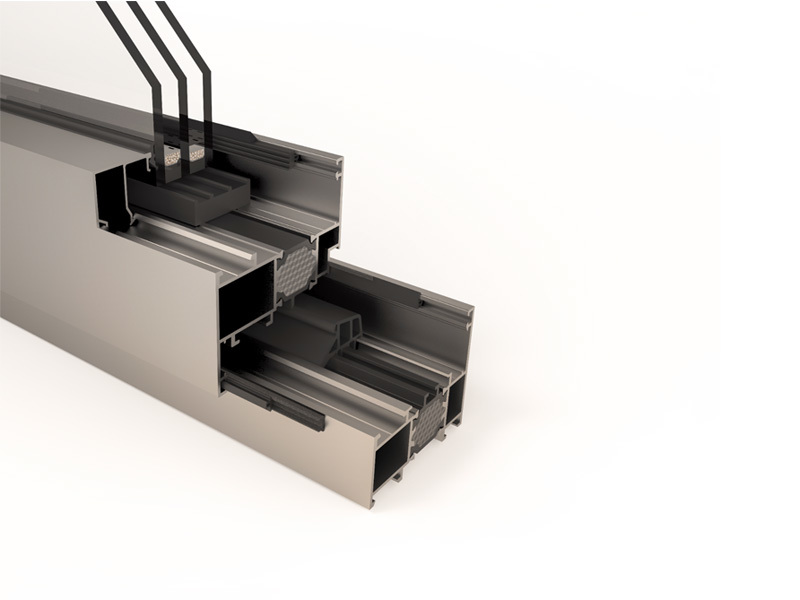

The use of equipment for the construction of doors and windows requires sealing strips to end the closure and sealing between the profile and the glass, and between the fan and the frame. The sealing strip plays a role in fixing the glass, buffering the oscillation and blocking the circulation of water and air in the use of doors and windows. The thermal insulation function and airtight function of doors and windows have a serious impact on the energy saving and consumption reduction of buildings. The heat loss of doors and windows with poor sealing is 5-6 times that of the wall. The energy-saving power of doors, windows and curtain walls accounts for about 37-40 percent of the energy-saving construction. Therefore, rubber strip is a kind of functional accessory that cannot be ignored in the energy-saving qualification of doors and windows. Its function and service life should attract our attention.