Inflatable sealing ring (airbag)

The material of the gas-filled sealing ring depends on the use environment, for example: (1) Silicone rubber material is used when high temperature is required; (2) EPDM rubber is used when aging resistance is required; (3) the presence of acid and alkali corrosion or oil pollution in the case of the use of nitrile rubber.

Key words:

- Commodity name: Inflatable sealing ring (airbag)

- Product Description

-

Product Introduction

1. The material of the inflatable sealing ring depends on the use environment, for example:

(1) Silicone rubber material is used when high temperature is required;

(2) EPDM rubber is used when aging resistance is required;

(3) the presence of acid and alkali corrosion or oil pollution in the case of the use of nitrile rubber.

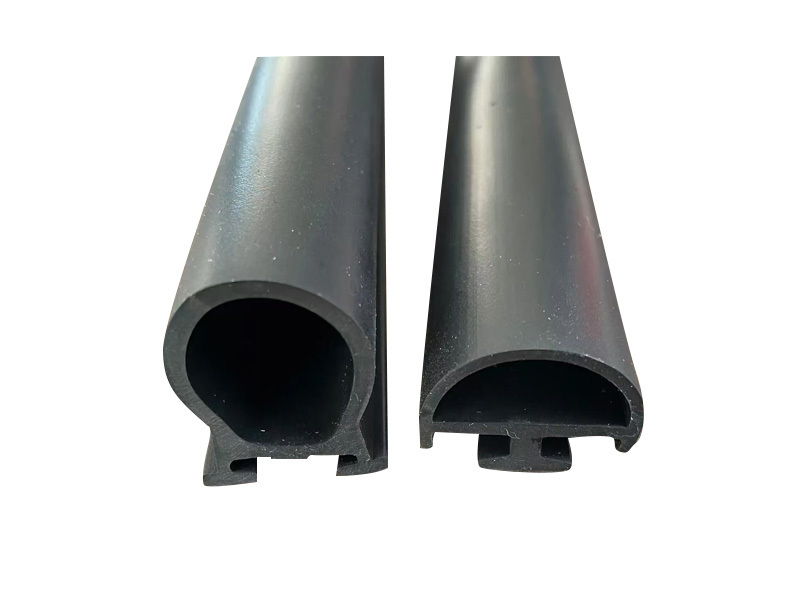

2. Shape and performance: The inflatable sealing ring is a hollow sealing ring made of rubber. The valve is installed on the ring body and connected to the air pump for pressurization and pressure relief. After inflation, the ring body expands elastically, and after deflation, the ring body completely retracts to its original shape. This mobile seal is its larger feature. According to the specific needs can be made into circles, square rings and linear capsules.

3. Working principle: The structure of the inflatable sealing ring is inflated to play a sealing role. Due to the flexible nature of rubber, the rubber hollow ring after inflation is plastic. After the contact between the expansion surface and the sealing surface, the flexible curve deformation occurs, so that the gap in the shape of a straight line or curve around the periphery (several meters-several hundred meters) can be sealed. After deflation, the sealing ring instantly returns to its original shape and the equipment gap reappears. It can be quickly and quickly sealed and unsealed, and the frequent use of inflation and deflation can reach 1 million times. In the working state, it is used for the gas pressure inside the ring body, and the sealing strength is large, so the air tightness is high and the sealing effect is good.

4. Section structure features: according to the seal gap size, fluid pressure, expansion and contraction frequency design of different ring body cross-section hollow structure shape. Such as round, trapezoidal, rectangular, M type, composite type, etc.

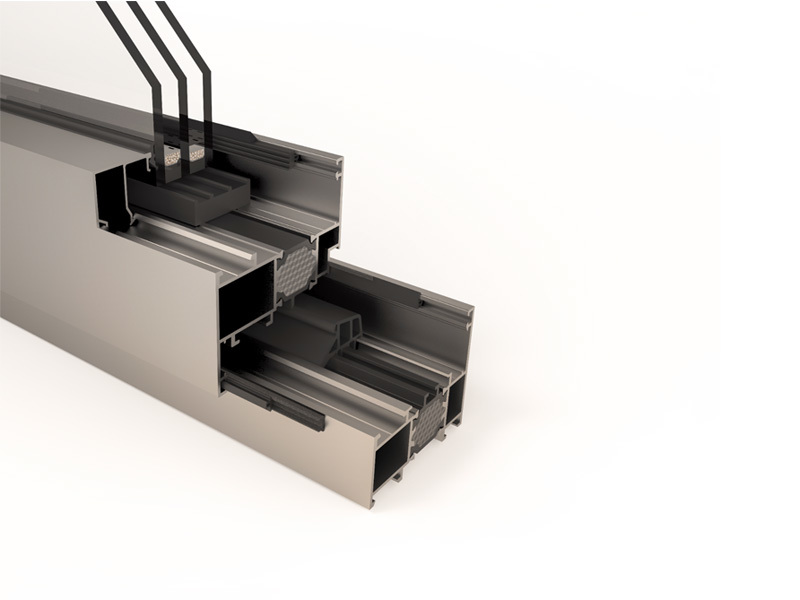

5 .. installation: inflatable sealing ring to be completely installed in the steel groove or hard PVC groove, to avoid the friction in the process of pushing and pulling.

6. Application: The inflatable sealing ring has good sealing effect and is simple and convenient to replace. It is being used by more and more industries.

1) Widely used in clean vacuum devices in the pharmaceutical, chemical, and food industries.

2) The materials in the production system are diverted and repacked.

3) industrial valves, piston control powder, viscous liquid.

4) Packing conveyor belt airlock, winding inflatable shaft device.

5) Electronic equipment, laboratory heat treatment

6) Transportation system.

7. Temperature resistance:-60-280 degrees.

8. Inflation pressure: 0.05-1.0Mpa, depending on the size of the cross-section and wall thickness.

Inquiry

Please leave your email and our professionals will contact you as soon as possible!

Recommended Products