Photovoltaic gap sealing strip

Photovoltaic gap seal is an important component used in photovoltaic systems. Its function is to provide sealing and protection at the gap between photovoltaic panels. Photovoltaic system is a device that uses solar energy to convert light energy into electrical energy. It is composed of multiple photovoltaic panels, and the gap between these photovoltaic panels is a key part of the photovoltaic system.

Key words:

- Commodity name: Photovoltaic gap sealing strip

- Product Description

-

Product Introduction

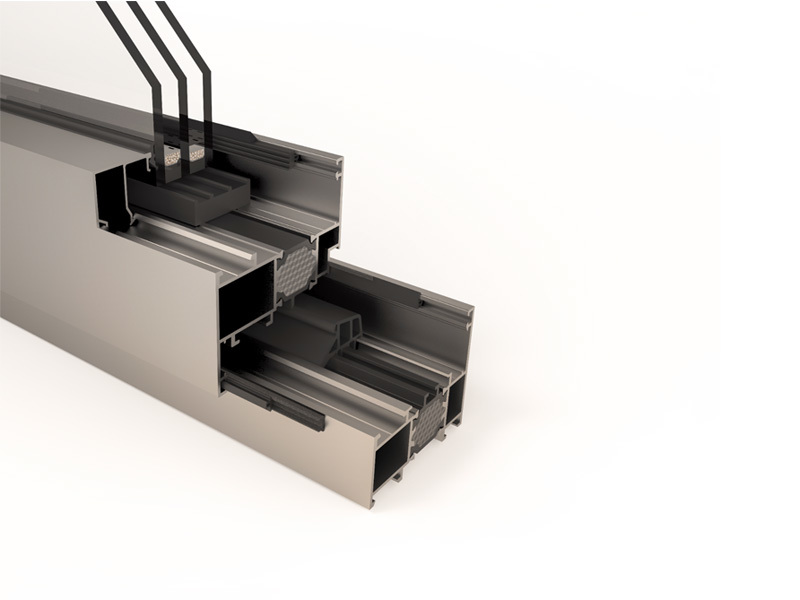

Photovoltaic gap sealing strip is an important component used in photovoltaic systems. Its function is to provide sealing and protection at the gap between photovoltaic panels. Photovoltaic system is a device that uses solar energy to convert light energy into electrical energy. It is composed of multiple photovoltaic panels, and the gap between these photovoltaic panels is a key part of the photovoltaic system.

2. The main function of the photovoltaic gap sealing strip is to prevent dust, moisture and other impurities from entering the gap between the photovoltaic panels, thereby protecting the normal operation of the photovoltaic panels. The photovoltaic panels will generate a certain amount of heat during the working process. If the gaps are not effectively sealed, the heat will cause the gaps between the photovoltaic panels to expand, thereby affecting the efficiency of the photovoltaic system. In addition, dust and moisture in the gap will also reduce the power generation efficiency of the photovoltaic panel, and even cause damage to the photovoltaic panel.

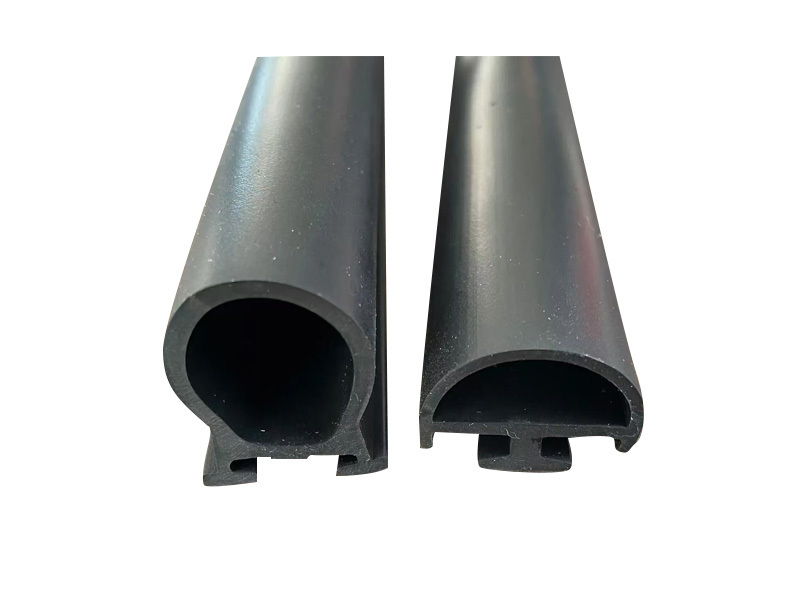

3. Photovoltaic gap sealing strip is usually made of EPDM material with good weather resistance.

Solar photovoltaic panel sealing strip has the effect of anti ultraviolet, weather resistance, heat aging resistance, low temperature resistance, ozone resistance, chemical resistance, water resistance, good electrical insulation and elasticity and other physical and mechanical properties, these advantages are PVC and other materials are not.

EPDM strips have excellent electrical insulation properties and corona resistance, and their electrical properties are better than or close to those of styrene butadiene rubber, chlorosulfonated polyethylene, polyethylene and cross-linked polyethylene.

EPDM strips can be used for a long time at 120°C and can be used briefly or intermittently at 150-200°C. Adding suitable antioxidant can increase its use temperature. EPDM rubber crosslinked with peroxide can be used under harsh conditions. EPDM rubber can reach more than 150h without cracking under the condition of ozone concentration and 30% stretching.

Inquiry

Please leave your email and our professionals will contact you as soon as possible!

Recommended Products