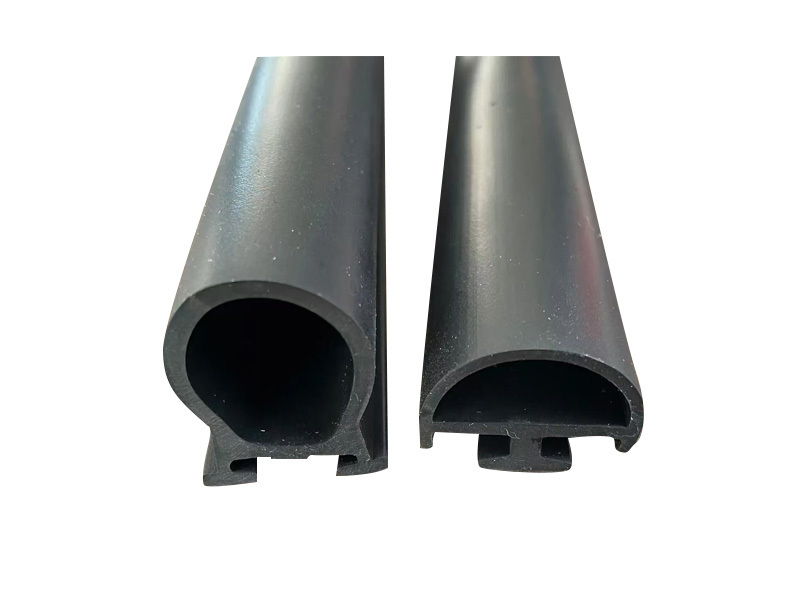

TPV cold weather strip

With the flexibility and elasticity of rubber, it can be produced by plastic processing methods, without vulcanization, and the waste can be recycled and reused.

Key words:

- Commodity name: TPV cold weather strip

- Product Description

-

Thermoplastic vulcanizate (TPV) weatherstrip

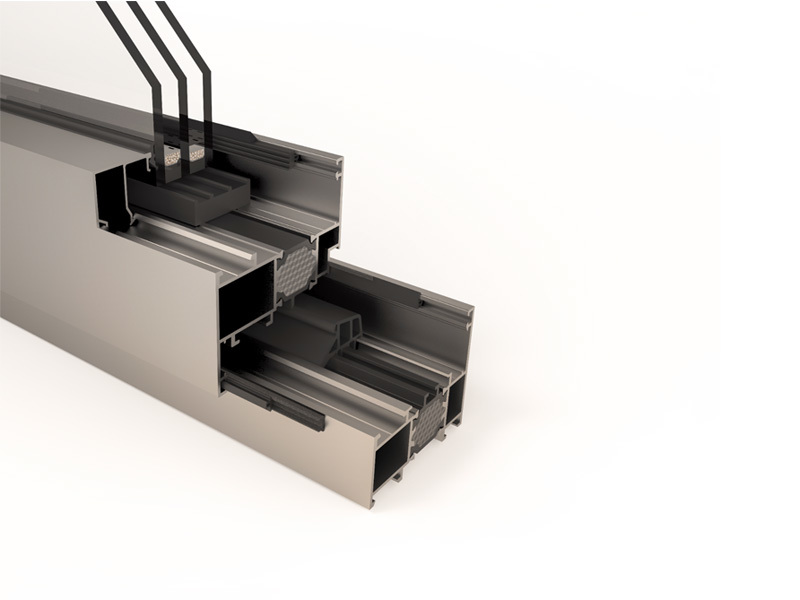

With the flexibility and elasticity of rubber, it can be produced by plastic processing methods without vulcanization, and the waste can be recycled and reused. Is a wide range of performance materials, heat resistance, cold resistance is good, relative density is small, oil resistance, solvent resistance and neoprene similar, resistance to compression deformation and wear resistance is not very good. Use temperature range -40~150 ℃. Can be applied to cold, as well as high-rise buildings.

TPV noun explanation: TPV is a kind of material, is by EPDM and PP blend, using dynamic vulcanization technology to mix the two substances into a stable elastomer.

Product Features:

1, environmental protection: no nitrite and other carcinogenic substances, no heavy metals, renewable use, to achieve health level, through SGS certification, in line with the EU ROHS directive.

2. Low density: only equivalent to 67% of ordinary EPDM sealing strip.

Good aging resistance: the service life under normal conditions is not less than 15 years.

4. Hardness changes little with temperature: the operating temperature can reach -60 ℃ to +130 ℃, and the hardness change is not 5HA in the range of -20 ℃ to +40 ℃, which is better than traditional PVC and common EPDM sealing strips.

5. Good resilience: under the conditions of compression rate of 30% and 70 ℃ x24h, the compression deformation is 25%; Under the same conditions, the ordinary sealing strip is 75%.

Inquiry

Please leave your email and our professionals will contact you as soon as possible!

Recommended Products