EPDM sealant strip

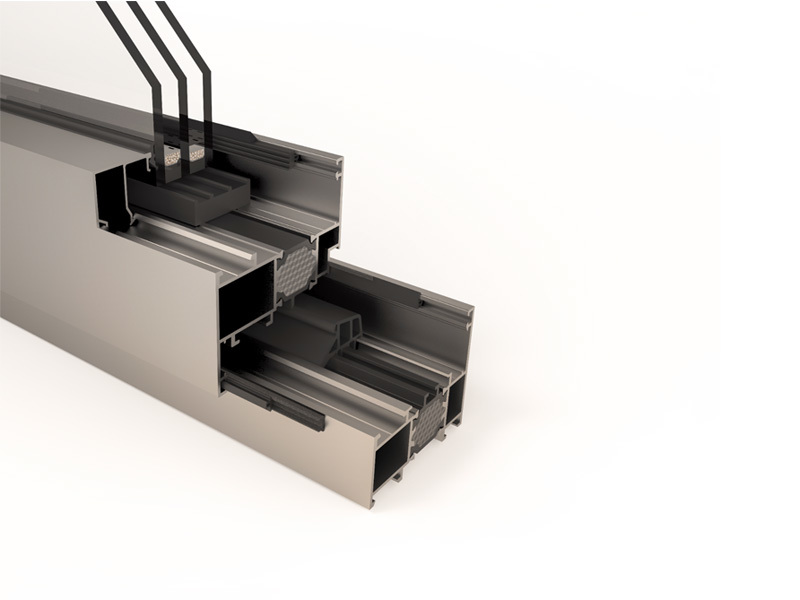

Sealing strips for doors and windows are mostly in the form of soft and hard co-extrusion composite, which can meet the hardness of the strip positioning itself and achieve good soft sealing of component coordination, reaching automobile grade materials. Some sealing strips are provided with equal pressure holes to achieve better sealing effect. The structural design of the sealing strip is very important. The excellent scheme design can effectively solve the problems of air leakage and water leakage of doors and windows and increase the service life of doors and windows;

- Commodity name: EPDM sealant strip

- Product Description

-

Product Introduction

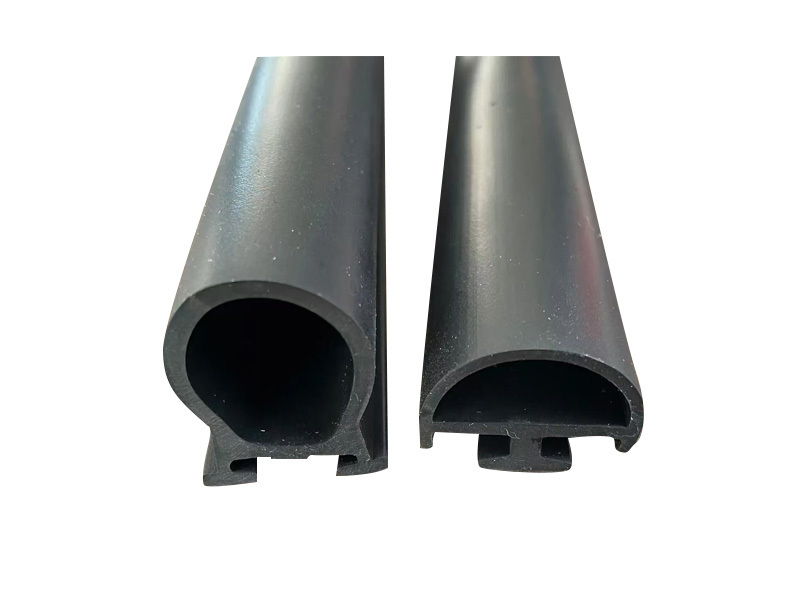

1. Composition: EPDM (EPDM) sealant strip is mainly composed of ethylene, propylene, and a small amount of third monomer non-conjugated diene copolymer.

2. Performance: EPDM sealant strip is added with special chemical auxiliary materials, which has excellent properties such as ultraviolet resistance, ozone resistance, chemical intervention resistance, acid and alkali resistance, water resistance, good insulation, elasticity and ultra-long aging resistance. At the same time, it has low temperature resistance and can be used for a long time in an environment of -50 ℃. Its molecular chain can also maintain flexibility and elasticity, and has strong high temperature resistance, in the raw materials and special DTDM,DPTT and other high-performance chemical accessories can be used for a long time at a temperature below 120 ℃, and can be used for a short time or intermittently at a temperature of 150-200 ℃.

3. Application: Sealing strips for doors and windows are mostly in the form of soft and hard co-extrusion, which can meet the requirements of positioning the hardness of the rubber strip and achieve good soft sealing of component coordination, reaching automobile grade materials. Some sealing strips are provided with equal pressure holes to achieve better sealing effect. The structural design of the sealing strip is very critical. The excellent scheme design can effectively solve the problems of air leakage and water leakage of doors and windows and increases the service life of doors and windows;Main performance parameters of EPDM

Hardness 68±2 Tensile strength 8MPa Elongation at break 400% permanent compression deformation <40% thermal aging (after 100 ℃ for 72h) Hardness 7A Tensile strength ≤-10% Elongation at break ≤-30% Low temperature parameters 0 ~-20 ℃ 24H hardness change 10A

-10 ℃ 7 days hardness change 8A

-10 ℃ 72H compression never deformation average 15.3Specification of EPDM sealing strip

► dense glue part sponge glue part

Applicable temperature -40~140 ℃ -35~150 ℃

► Hardness 50~80 ℃ A 10~30 ℃

► Tensile strength (>)≥ 10-

► Elongation at break (>)200~600 200~400%

► Compression set 24 hours 70(x)35% 40%

Density 1.2~1.35 0.3~0.8

Door and window sealing strips are divided into three categories: glass sealing strips (rubber strips), door leaf sealing strips and wool strips,

The glass sealing strip is used for sealing between the glass and the leaf and the frame, the door leaf sealing strip is mainly used for sealing between the door panel and the door frame, and the wool strip is mainly used for sealing between the frame and the leaf.

In the production and installation of plastic steel doors and windows and broken bridge aluminum doors and windows, wooden doors, sealing strip is an essential accessory. It is mainly used for plastic steel doors and windows, broken bridge aluminum doors and windows and wooden doors to ensure the fastening of rubber strips and profiles.

The sealing strip needs to have strong tensile strength, good elasticity, and good high temperature resistance and aging resistance.

The functions of door and window sealing strips mainly include waterproof, sealing, energy saving, sound insulation, dustproof, antifreeze and heat preservation.

The door and window sealing strips on the market are generally extruded from PVC, modified PVC, EPDM, elastomer sealing strips (including TPV, TPE, TPR, SEBS), silicone and other materials.

EPDM rubber strip has excellent UV resistance, weather resistance, heat aging resistance, low temperature resistance, ozone resistance, chemical resistance, water resistance, good electrical insulation and elasticity and other physical and mechanical properties. These advantages are irreplaceable by other materials such as PVC.

Inquiry

Please leave your email and our professionals will contact you as soon as possible!

Recommended Products